On June 24, at around 10:31 a.m. local time, a fire broke out at a lithium battery factory in an industrial park in Hwaseong, Gyeonggi Province, South Korea. According to South Korean police, the death toll in the accident has now risen to 23. Based on preliminary judgment such as personal belongings, 17 Chinese citizens were killed.

The Aricell factory where the fire broke out is located in a three-story building with a reinforced concrete structure. The warehouse stores 35,000 finished lithium batteries. Witnesses believed that one of the finished lithium batteries exploded.

According to the National Fire Protection Association, physical damage, product defects or circuit damage may cause a "thermal runaway" chain reaction in lithium batteries. When the internal temperature of the battery rises to a certain level, the battery material will release a large amount of heat. The rapid increase in battery temperature will eventually cause the battery to catch fire or explode.

The so-called "thermal runaway" means that the battery system overheats and cannot be effectively controlled or cooled due to some reasons, ultimately causing serious safety hazards. This risk is particularly taken seriously in the electric vehicle industry.

In order to ensure that the battery does not burn, explode, or even heat spread during use, and avoid thermal runaway, what can heat-proof and flame-retardant materials do?

New energy vehicles strengthen the prevention of battery thermal runaway in both active and passive aspects.

Active management means that the cooling water loop in the heat pump system cools/heats the three-electric system and adjusts it through active control of the system.

Passive management mainly plays the role of heat insulation, flame retardant, precise humidity control, etc. It controls the heat transmission through the selection of materials, and plays a direct and key protective role for passengers in the event of thermal runaway.

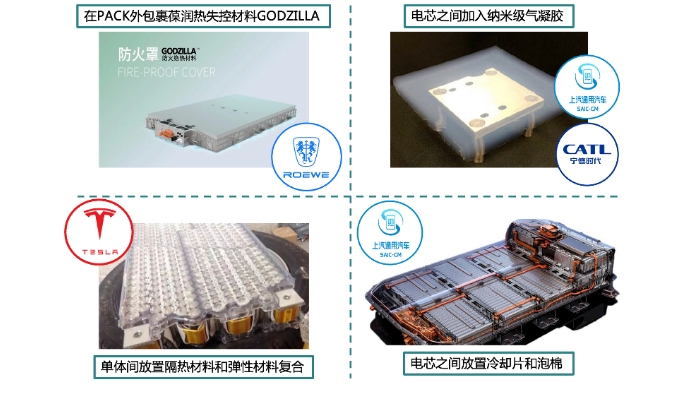

Top car companies and battery manufacturers work together,Research thermal runaway protection material solutions

Different batteries use different fireproof and thermal insulation materials. Due to the different expansion rates, specific surface areas, and ease of thermal runaway of cells of different shapes, different automobile companies use different fireproof and thermal insulation materials for heat insulation.As battery energy density increases and higher safety requirements are imposed, the industry chain Downstream companies are actively deploying related products.Power lithium battery manufacturers such as CATL and China Innovation Aviation use materials such as airgel felt to improve the thermal protection and control performance of battery packs. Currently, nitride aerogels and carbide aerogels are in the research and development stage.In addition to battery manufacturers, OEMs are also involved in battery PACK design, proposing new technical solutions in terms of heat insulation and flame retardant materials, such as the Baorun Godzilla "fireproof cover" product used in SAIC Roewe ER6. Material manufacturers such as Pan Asia Micro-Penetration have also begun to conduct research on thermal pad composite material technology.

Technical strength and overall service capabilities are crucial to material suppliers

Recently published test results from engineering plastics supplier Saudi Basic Industries Corporation (Sabic) highlight the potential of thermoplastic-based thermal runaway barrier solutions to prevent the spread of fires in electric vehicle (EV) batteries.Saudi Basic Industries Corporation's (Sabic) subsystem-level test series has shown that battery module boxes made from the company's Stamax 30YH570 long glass fiber polypropylene (PP) resin, with cell-to-cell thicknesses as thin as 1 mm, have the ability to prevent 18650 cylindrical The potential for thermal runaway propagation in shaped batteries.

Stamax grades reportedly provide the necessary thermal insulation and flame retardancy to reduce the chance of cell-to-cell spread in the event of thermal runaway, thereby reducing the risk of catastrophic safety incidents. This material, combined with compressible foams, has also shown promising results in controlling the propagation of thermal runaway in prismatic and pouch batteries.

In order to meet the safety requirements of electric vehicle battery components, Solvay has launched a new solution for battery applications that require resistance to thermal runaway and heat insulation propagation. Xencor™ Designed for components.

Key benefits of this solution include high stiffness, strength and impact resistance, best-in-class electrical insulation (relative tracking index >600 volts) and high dielectric strength, while the range is partially bio-based and 100% renewable Electricity production.

Xencor™ XTreme PPA LGF grades provide resistance to direct flame exposure to 1000°C for more than 10 minutes, providing passengers with sufficient time to exit the vehicle in the event of thermal runaway.

This series of materials maintains excellent levels of electrical insulation after exposure to flame, helping to mitigate thermal runaway in batteries. Features a high glass transition temperature (Tg) to ensure component dimensional stability under battery operating conditions.

Polyplastics has developed a material that helps with heat and insulation - DURAFIDE® PPS 6150T73.

Even after the material is placed in an environment of 1000°C for 30 minutes, the state of the busbar sheath can remain unchanged. Therefore, this resin material can contribute to thermal insulation and insulation in the event of thermal runaway without the need for inorganic sheets.

In addition to its exceptional heat resistance, the material also has optimal properties for applications such as module covers and busbars in lithium-ion batteries.

The "Special Flame-Retardant Continuous Fiber Thermoplastic Composite Material (Special Flame-Retardant CFT)" jointly developed by LG Chem and LX Hausys is characterized by being more than 14 times longer than existing composite materials under high-temperature flames and high pressures.

Special flame-retardant CFT can be used in the top and bottom covers of large battery packs in electric vehicle batteries because of its high hardness and small deformation due to force.When an electric vehicle catches fire, it can effectively delay the spread of the fire and buy the driver the necessary time to evacuate and put out the fire.

LG Chem's experimental results show that when a special flame-retardant CFT with a thickness of 1.6mm was placed in a hot pressing environment above 1500°C, no melting or cracks were found after 20 minutes, and the flame barrier performance reached the industry-leading level.

This special flame-retardant CFT applies LG Chem’s delayed battery thermal runaway material technology and LX Hausys’ thermoplastic composite material (CFT, continuous fiber thermoplastic) manufacturing technology.

This time, LX Hausys adopted a manufacturing process in which LG Chem’s materials were made into tape forms and stacked to further improve the flame barrier performance.

If you are also troubled by the problem of high heat-resistant and flame-retardant plastic materials, please feel free to consult Qingdao PRIME Union TRADE CO.,LTD.

QINGDAO PRIME TRADE CO., LTD is a company with more than 20 years of experience that specializes in distributing international brand engineering plastic particles. It mainly represents: CHIMEI ABS, HANWHA TOTAL PP, SABIC PPO, PC special materials, LG Chem, Solvay, etc.We also have our own modified processing factory, Qingdao Primetech Plastic Co., Ltd. , with a professional technical team to provide you with fast and professional services to meet the needs of customers at different levels.

0086 13605427277

0086 0532 68051919

0086 157 2520 9359