In the rapidly developing automobile industry, every detail is related to driving comfort, safety and the overall performance of the vehicle. Among them, the automobile sealing strip is a key component that connects various components of the car body and isolates external noise and wind and rain. Its material selection and performance improvement are particularly important. In recent years, with the continuous advancement of material science, the composite application of TPE (thermoplastic elastomer) and EPDM (ethylene propylene diene monomer) - TPE+EPDM automotive sealing strips, is gradually becoming a new favorite in the market, leading automotive sealing technology of innovation.

TPE and EPDM: the perfect combination of complementary advantages

TPE, as a new type of material that combines rubber elasticity and plastic processing properties, has excellent weather resistance, aging resistance, low-temperature flexibility, and recyclable and reusable environmental features.

EPDM, as a traditional automotive sealing material, is famous for its excellent ozone resistance, heat resistance, weather resistance and good electrical insulation properties.

By cleverly combining these two materials, TPE+EPDM automotive sealing strips not only inherit their respective advantages, but also achieve a qualitative leap in performance.

TPE and EPDM have significant performance advantages

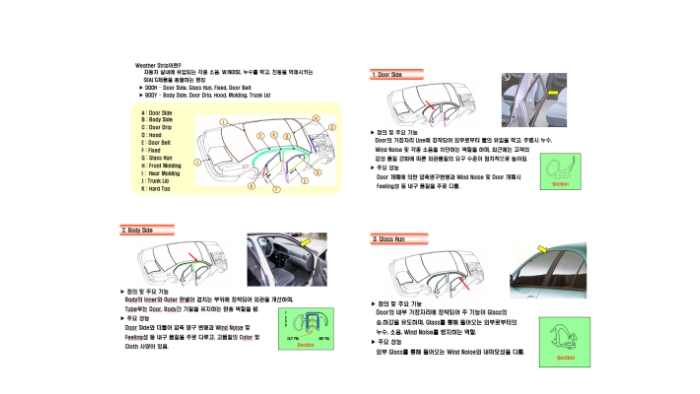

Excellent sealing performance: The flexibility of TPE and the sealing performance of EPDM complement each other, allowing the TPE+EPDM sealing strip to maintain a stable sealing effect under extreme temperature conditions, effectively blocking external noise, dust and water vapor, and improving the quietness of the interior environment of the car and cleanliness.

Weather resistance and aging resistance: After combining the two, the weather resistance and aging resistance of the material are significantly enhanced, and it can resist the influence of harsh environmental factors such as ultraviolet rays, ozone, high temperature, and low temperature for a long time, and extend the service life of the sealing strip.

Good processing performance: The thermoplasticity of TPE makes composite materials easy to process and shape, improving production efficiency and reducing production costs. At the same time, this also provides more possibilities for personalized customization of sealing strips to meet the design needs of different models.

Environmentally friendly and sustainable: The recyclability of TPE materials makes TPE+EPDM seals more environmentally friendly when discarded, in line with the current global pursuit of green travel.

TPE and EPDM materials have broad application prospects

As consumers' requirements for automobile quality continue to increase, and the automobile industry continues to pursue lightweighting, energy conservation and emission reduction, TPE+EPDM automobile sealing strips have broad application prospects. It is not only suitable for doors, windows, engine hoods and other parts of traditional fuel vehicles, but also shows great potential in the field of new energy vehicles, especially playing an important role in the waterproof, dustproof and wind noise control of electric vehicles.

The advent of TPE+EPDM automotive sealing strips marks that automotive sealing technology has entered a new stage of development. It not only improves the overall performance and comfort of the car, but also promotes the sustainable development of the automotive industry. In the future, with the continuous breakthroughs in material science and the continuous progress of automobile technology, we have reason to believe that TPE+EPDM automobile sealing strips will play an important role in more fields and bring drivers a safer, more comfortable and environmentally friendly travel experience. .

ExxonMobil Santoprene 101-73 is currently widely used in the market. It is widely used in the automotive field due to its excellent physical properties and chemical resistance. But do you want to reduce costs? We currently have better TPE+EPDM materials, which are nearly 50% cheaper than ExxonMobil and have been used in modern cars. If you want to know more, please contact us!

QINGDAO PRIME TRADE CO., LTD is a company with more than 20 years of experience that specializes in distributing international brand engineering plastic particles. It mainly represents: CHIMEI ABS, HANWHA TOTAL PP, SABIC PPO, and PC special materials.We also have our own modification processing factory, Qingdao Primetech Plastic Co., Ltd., with a professional technical team to provide you with fast and professional services to meet the needs of customers at different levels.

0086 13605427277

0086 0532 68051919

0086 157 2520 9359