Conspectus:

Medical PP plastic has high transparency, good barrier properties and radiation resistance, making it widely used in medical equipment and packaging industries.

Medical PP plastic is colorless, odorless and non-toxic. It is a thermoplastic with excellent performance and has the advantages of small specific gravity (0.9g/cm3), non-toxic, easy processing, impact resistance, and flexural resistance.

Medical PP plastic is a semi-crystalline material with a high melting point and good heat resistance. The yield strength, tensile strength, compressive strength, hardness and elasticity are higher than those of polyethylene (PE). In addition, it must be resistant to gamma ray sterilization.

Case Studies:

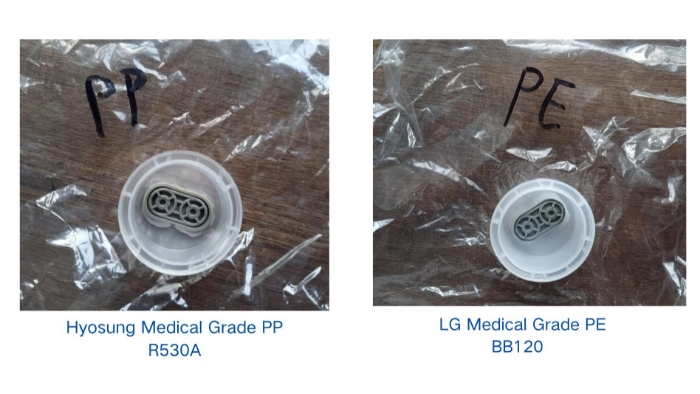

Are you looking for a supplier of medical grade PP? We recently received a medical PP consultation from a medical device company - they produce IV bottles and ampules, and the materials they have been using are LyondellBasell's medical grade PP RP270G and medical grade LDPE 3220D to produce their IV bottles caps. But due to supply stability issues and price issues, they are currently looking for new suppliers. After our engineers communicated with the manufacturer, we recommended Hyosung medical grade PP R530A and LG medical grade PE BB120 to them. The customer purchased some samples and went back for testing. The tested samples are shown in the picture below.

It is usually not that simple to replace raw material manufacturers for medical materials. Medical-grade PP/PE raw materials usually need to meet specific quality standards and regulatory requirements to ensure that they are safe, reliable and suitable for the manufacturing of medical devices and medical supplies. These standards may involve aspects such as the purity of raw materials, control during production, selection of additives, etc. China requires that medical-grade PP/PE must pass GB/T 16886 biocompatibility certification. The commonly used international standard is ISO 10993 testing. Only PP/PE materials that pass these certifications can be used in medical devices and medical consumables.

So do Hyosung medical grade PP R530A and LG medical grade PE BB120 meet the relevant medical testing standards?

South Korea's Hyosung's medical grade PP R530A can be steam sterilized, has passed biocompatibility certification, and complies with testing standards such as DMF 21499/EU EP 3.1.6/FDA 21 CFR 177.1520/USP Class VI.

LG Chem's medical grade PE BB120 can be sterilized within 50 minutes at 109°C and meets testing requirements such as FDA 21CFR 177.1520/USP Class VI.

Therefore, Hyosung Medical PP R530A and LG Chem Medical PE BB120 are widely used in IV bottles and ampules, liquid pharmaceutical packaging bottles, etc.

If you need to obtain relevant TDS and certificates, please contact us---Qingdao Prime union Trading Co., Ltd.

So are the prices and supply of goods advantageous? We have four major advantages:

1.Qingdao prime union Trading, are the direct distributors and first-level agents of Hyosung and LG Chem in South Korea;

2. Qingdao Prime union Trading has multiple warehouses with stable supply, sufficient inventory and fast delivery;

3. Qingdao prime union Trading Warehouse is close to Qingdao Port, one of China's largest ports, with convenient transportation and low transportation costs;

4.Qingdao prime union Trading’s business radiates to Asia, Europe, South America and other regions;

If you are a medical product injection molding manufacturer or trader, please pay attention to our website of Qingdao prime union Trading Co., Ltd. Qingdao prime union Trading, established in 2002, is the authorized agent and distributor of CHIMEI, Hanwha TotalEnergies, SABIC, LyondellBasell, Kumho of South Korea, Borouge/Borealis, and distributes ABS, PS , AS, PMMA, ASA, PC/ABS alloy, PC, PPO, PP, PE and other materials. Chimei's ABS, AS, PS, PC, etc., and some of Hanwha Total Energy's PP, all meet medical grade requirements. We will give you a detailed introduction to other medical grade ABS, PC, PS products, etc. in later articles.

In addition, our Brother company, Qingdao Primetech Plastic Co., Lt., was established in 2007 and is mainly dedicated to the research and development and customized production of modified plastics. If you have needs for medical grade masterbatch, you can also contact us for customized production. The medical grade masterbatch we produce has passed the GB/T16866 biocompatibility test and is used in the production of blood collection bottle caps, infusion tube regulators, etc.Our engineers can provide you with technical guidance to ensure stable production of your factory,

Thank you for your attention to Qingdao Prime union Trading co.,ltd

0086 13605427277

0086 0532 68051919

0086 157 2520 9359