The lightweight potential of every automotive component is being studied. This includes internal combustion engines (ICE) and electric vehicles (EV). Advanced plastics and plastic composites can significantly improve vehicle performance.

Fiber-reinforced engineering plastic composites are 25-35% lighter than steel components of the same strength. Uses of new materials also include:

1.greater use of plastics/composites in body panels;

2.Long continuous fiber technology for structural parts;

3.Parts such as structural parts are increasingly using carbon fiber reinforced plastics due to the development of low-cost composite materials;

4.polycarbonate and acrylic as glazing for roofs, headlights and taillights;

5.Advanced nylon under the hood.

Plastics suppliers are also customizing materials to meet automotive sustainability and lightweighting goals.

SABIC (EV) Formula E Racing Materials

Genbeta is the world's leading electric vehicle (EV) Formula E race car. It set a Guinness World Record at the recent world's first all-electric FIA World Championship. The record is the fastest speed achieved indoors. The speed achieved was 218.71 kph (kilometers per hour) or 135.9 mph (miles per hour).

Its key thermoplastic components include:

Front wing end panels – The front wing end panels are 3D printed in a variety of materials. For example, polypropylene (PP) copolymer, polycarbonate (PC) or polybutylene terephthalate (PBT)/PC blends. They are mounted on the outer ends of the vehicle's front wings. They are integral to redirecting airflow over the front wheels. They reduce drag while maintaining the car's downforce and stability.

Wheel Fins – Wheel fins are injection molded parts. They use SABIC machinery to recycle thermoplastics such as STAMAX™ polypropylene (PP) copolymer. It contains post-consumer waste based on TRUCIRCLE™ circular materials. They are mounted on the rim in a pattern of radial spokes. This in turn optimizes airflow. It also reduces aerodynamic drag for higher speeds and cools the brakes for improved stopping power.

Wind deflectors – Wind deflectors are extruded clear polycarbonate (PC) sheet components. They use biorenewable low-carbon materials from SABIC’s TRUCIRCLE™ product portfolio. They are mounted at the front of the racing cockpit, in front of the driver. As a result, it optimizes airflow to reduce drag and ultimately improve speed performance.

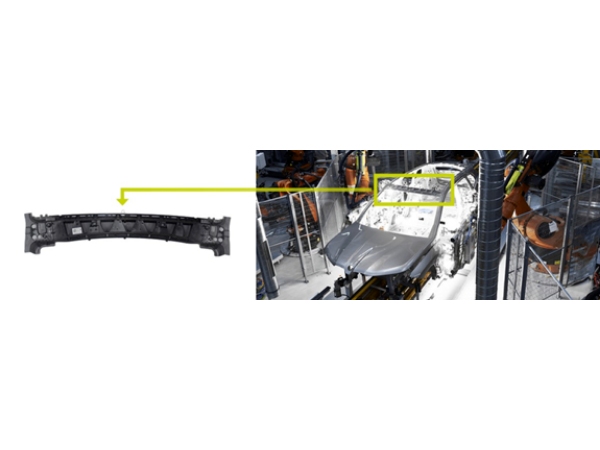

Wipag PA6 applied to windshield beams

Weipag polyamide 6 recycled carbon fiber composite is used in the windscreen crossmembers of the BMW iX electric vehicle (EV). The superstructure components of electric vehicle windshields are made of WIC PA6 15 BK IM compound. It uses injection-molded metal hybrid technology, utilizing carbon fiber waste from BMW's carbon fiber composites manufacturing unit.

The windshield structural cross member, also composed of metal inserts and carbon fiber rods, is an impact-modified grade that offers the following benefits:

1.Good mechanical performance

2.Lightweight, sustainable, circular economy alternative solutions

In addition to meeting mechanical requirements, recycled carbon fiber also reduces the carbon footprint. One kilogram (kg) of WIC PA6 releases approximately 6 kilograms of CO2 equivalents (eq.), while manufacturing from 1kg of virgin carbon fiber releases approximately 9 kilograms of CO2 equivalents.

GS-Caltex LFT improves dimensional stability of skylight frames

GS-Caltex’s HiPrene® ALG14BF polyamide 6 long-fiber thermoplastic (LFT) compound is used in the panoramic sunroof frame of the Hyundai-Kia Sorrento. South Korea's Inalfa Roof Systems injection molds the skylight frame using GS-Caltex compound.

This is the first time flat glass fibers have been used instead of traditional round glass fiber reinforcements. This provides the skylight with the following properties:

1. Improve dimensional stability

2. Reduce warpage

Torsion pultrusion is a new technology used to produce LFT pellets. This makes the fibers longer than the plastic particles. It improves mechanical properties.

The parts are 51% lighter compared to the previous standard steel frame. The total number of parts consolidated dropped from 33% to 4%.Glass-filled LFT has a 13% increase in bending and torsional stiffness compared to carbon fiber-reinforced LFT. Likewise, it achieved a 25% improvement in part breaking force at a 24% cost reduction.

Solvay has developed its latest high-temperature resistant liquid crystal polymer (LCP), Xydar® LCP G-330HH. This LCP compound grade is inherently flame retardant and does not require the use of halogen or bromine additives.It maintains electrical insulation properties after 30 minutes of exposure to 752°F (400°C). It has the following characteristics:

1glass filled;

2.easy to flow;

3.Can be injection molded.

Automakers are switching the voltage of next-generation electric vehicles (EVs) from 400V to 800V. This is because global regulations are increasing the heat resistance of battery components. They need to withstand temperatures from 300°C to 1000°C for up to 15 minutes.

Xydar® LCP G-330 HH improves safety by allowing passengers sufficient time to exit the electric vehicle in the event of a battery thermal runaway fire.Its target application is thin-wall insulation panels for electric vehicle battery modules with thin-wall dimensions of 100x150x0.5 millimeters (mm).

DOMO Recycled PA for Automotive and Other Applications

DOMO developed TECHNYL® 4EARTH® polyamide 6 (PA6 or nylon 6) and polyamide 66 (PA66 or nylon 66). It reduces the environmental impact of polyamide parts to levels never achieved before, as evidenced by the life cycle results.

It emits 80% less CO2, uses 70% less water, and uses 60% less energy in the manufacturing process. These grades target recycled content of 20% or more. They contain up to 50% carbon fiber or glass fiber.

Main applications include:

1. Automotive bearing cages, transmission cases, oil pans, oil separators, cylinder head covers, intake manifolds and transmission covers;

1. Electrical, household and garden appliances;

1. Consumer/industrial products such as insulation/window profiles, furniture components, industrial components, sports and leisure equipment, and agricultural implements.

Covestro Recycled PC for transparent headlight covers

Covestro brings its circular economy polycarbonate (PC) expertise to the Nalyses automotive headlight project. It is funded by the German Federal Ministry of Education and Research, led by Hella.It specializes in the development and design of today's transparent headlight covers. It also focuses on their reuse, remanufacturing or end-of-life material recycling. This move aims to create a high-value recycled PC raw material base covering the entire product life cycle.

Covestro conducted research on modular headlight concepts. This is based on different types of polycarbonate and is designed to reduce: assembly steps, space requirements, costs, and CO2 emissions.

Focusing on one plastic (such as designated PC) can reduce labor costs. There are labor costs involved in separating, sorting and storing it in the recycling stream without sacrificing performance. The Nalyses consortium includes Hella (headlights), Covestro, BMW, geba Kunststoff compounds, Fraunhofer Institute for Mechatronic Systems IEM, Heinz Nicksdorf Institute and Hamm-Lipsch Tate University of Applied Sciences.Their project results are planned to be transferable to other industries.

QINGDAO PRIME TRADE CO., LTD is a company with more than 20 years of experience that specializes in distributing international brand engineering plastic particles. It mainly represents: CHIMEI ABS, HANWHA TOTAL PP, SABIC PPO, and PC special materials. We also have our own modification processing factory, Qingdao Mattel Plastic Co., Ltd., with a professional technical team to provide you with fast and professional services to meet the needs of customers at different levels.

0086 13605427277

0086 0532 68051919

0086 157 2520 9359