Introduce:

Acrylic is polymethyl methacrylate (PMMA). It is a polymer polymerized from methyl methacrylate. It is also called organic glass and has high transparency, high weather resistance and high hardness. , easy processing and molding and other advantages, it is a frequently used glass alternative material.

The relative molecular mass of PMMA is about 2 million, and the chains forming the molecules are relatively soft. Therefore, PMMA has relatively high strength, and its tensile and impact resistance is 7 to 18 times higher than ordinary glass. When used as organic glass, even if it is broken, it will not produce fragments like ordinary glass. PMMA is the transparent polymer material with the best optical properties at present, with a light transmittance of 92%, which is higher than that of glass and PC. , which has also become the most important basic feature for many of its applications.

PMMA's weather resistance is also second to none among commonly used plastics. Under the automotive exterior weather resistance test standard SAE J2527, it can meet the weather resistance test of 3500-4000 KJ/m2, which is much higher than ordinary PC, PA and other plastics. In addition, PMMA's pencil hardness can reach 2H, which is much higher than other ordinary plastics such as PC, and has good surface scratch resistance.

The research and development of acrylic has a history of more than 100 years.

The polymerizability of acrylic acid was discovered in 1872;

The polymerizability of methacrylic acid was known in 1880;

In 1901, research on the synthesis method of propylene polyacrylate was completed;

In 1927, industrial manufacturing was attempted using the aforementioned synthesis method;

In 1937, the industrial manufacturing of methyl esters was successfully developed, thus entering into large-scale manufacturing

During World War II, due to its excellent strength and light transmittance, acrylic was first used in aircraft windshields and tank driver's cab vision mirrors. Trinseo's Plexiglas@ brand was the first to commercially produce PMMA sheets in North America.

Next, what characteristics PMMA has?

High transparency: PMMA has good light transmittance, which can reach more than 90%, close to glass. This makes it an ideal alternative for making transparent products such as display cabinets, glasses, etc.

Strong weather resistance: PMMA has excellent weather resistance, can resist ultraviolet radiation and oxidation, and is not prone to yellowing and aging. Therefore, it is widely used in outdoor signs, billboards and other products that require long-term exposure to sunlight.

Good processing performance: PMMA has good thermoplasticity and can be formed through various processing methods such as injection molding, extrusion, and calendering. At the same time, it can also perform secondary processing such as cutting, drilling, and polishing, giving it greater design flexibility.

Application of PMMA in life

Due to its excellent properties, PMMA has been widely used in automobiles, electronics and home appliances, consumer goods, lighting, construction and building materials, medical and other fields.

Construction field: PMMA can be used to make transparent roofs and skylights to provide indoor lighting and landscape viewing effects. At the same time, it can also be used to make facade decorations, partition walls, etc., to create a unique space atmosphere.

Advertising industry: PMMA has good optical properties and weather resistance, and is suitable for making outdoor billboards, light boxes and other promotional materials. Its high transparency and anti-UV properties make advertising content more vivid and durable.

Electronic products: PMMA can be used as display material for electronic products, such as mobile phone screens, touch screens, etc. Its high transparency and wear resistance provide users with a better visual experience and service life.

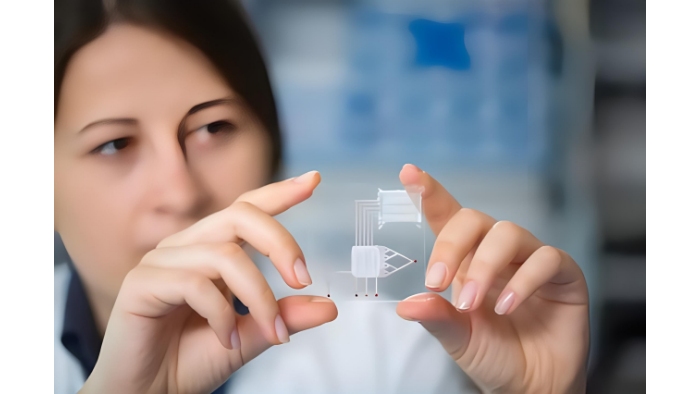

Medical devices: PMMA is widely used in the manufacturing of medical devices, such as intraocular lenses, braces, transparent catheters, etc. It has good biocompatibility and optical properties and meets the requirements of the medical industry.

To sum up, PMMA, as a plastic material with excellent transparency and weather resistance, is widely used in construction, advertising, electronics, medical and other fields. It not only has good optical properties, but also has good processing properties, providing more space for creation and application in various industries. It is believed that with the continuous development of technology, the application fields of PMMA will become more and more extensive.

Chimei is the world's largest acrylic PMMA manufacturer. The PMMA particles it produces (CM-205, CM-207, CM-211...) have clear transparency and high gloss, as well as stable physical, chemical, and Optical and electrical properties. Widely used in electronic panels, mechanical parts, watch surfaces, car lights, telecommunications equipment, insulation parts, sunglasses, food and water contact materials, cosmetic containers and toys, compliant with RoHS, REACH SVHC, UL and various international standards, suitable for various kind of application use.

Qingdao Primeunion Trading is an authorized dealer of Chimei. It has been an agent for Chimei's raw materials since 2002, and deals in Chimei's ABS/GPPS/HIPS/AS/PMMA/PC/PC+ABS alloy and other materials. It has offices in Zibo and Qingdao. There are sales offices and warehouses with sufficient raw material inventory and can be shipped at any time. The company is registered in the Qingdao Bonded Port Zone and has the right to operate import and export operations. It can conduct intra-area re-export trade, customs manual trade (customs supervision), US dollar general trade, etc. At the same time, the sister company Qingdao primetech Plastic is an experienced modification factory with 16 years of experience and can provide one-stop service for plastic modification, dyeing, and injection molding process support. If you have any needs for Chimei PMMA , please feel free to call us or leave a message/communicate online.

0086 13605427277

0086 0532 68051919

0086 157 2520 9359